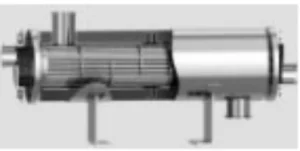

SOLLAIR 100% oil-free screw compressor is a flagship product in our company’s oil-free compressor series.

100% Oil-Free Air: Adheres to ISO 8573-1:2010 Class 0 standards, specifically designed for air quality in industries such as food and beverage, pharmaceuticals, textiles, and electronics.

Energy Efficiency: The air end incorporates an optimized rotor profile, achieving a notable 13.5% improvement in efficiency and leading airflow capacity for enhanced energy conservation.

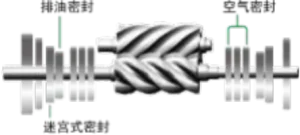

Enhanced Reliability: Equipped with stainless steel components, dual-vented seals, and precision-machined rotors featuring advanced “Ultra Coating” protection, ensuring trouble-free operation and heightened reliability.

Ease of Maintenance: Drastically reduce maintenance expenses with extended maintenance intervals and patented long-life consumables, ensuring optimal performance while minimizing the need for replacements.

High Ambient Operation: Engineered with durable components capable of withstanding a maximum ambient temperature of 46°C. Additionally, an optional High Ambient package is available, designed to endure a maximum ambient temperature of 55°C, further enhancing operational resilience.