Sollair 2- stage rotary screw air compressor features a superior end-to-end design for optimum efficiency and power savings:

● Self-developed variable speed technology which increases efficiency and offers energy savings.

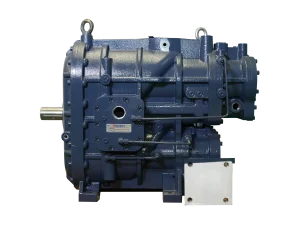

● SKF Bearing , INGERSOLL RAND / Rotor Comp Air End(optional)

● Enhanced stability and reliability as well as cost-effectiveness.

● Reduce power consumption by around 35% compared to traditional frequency machines.