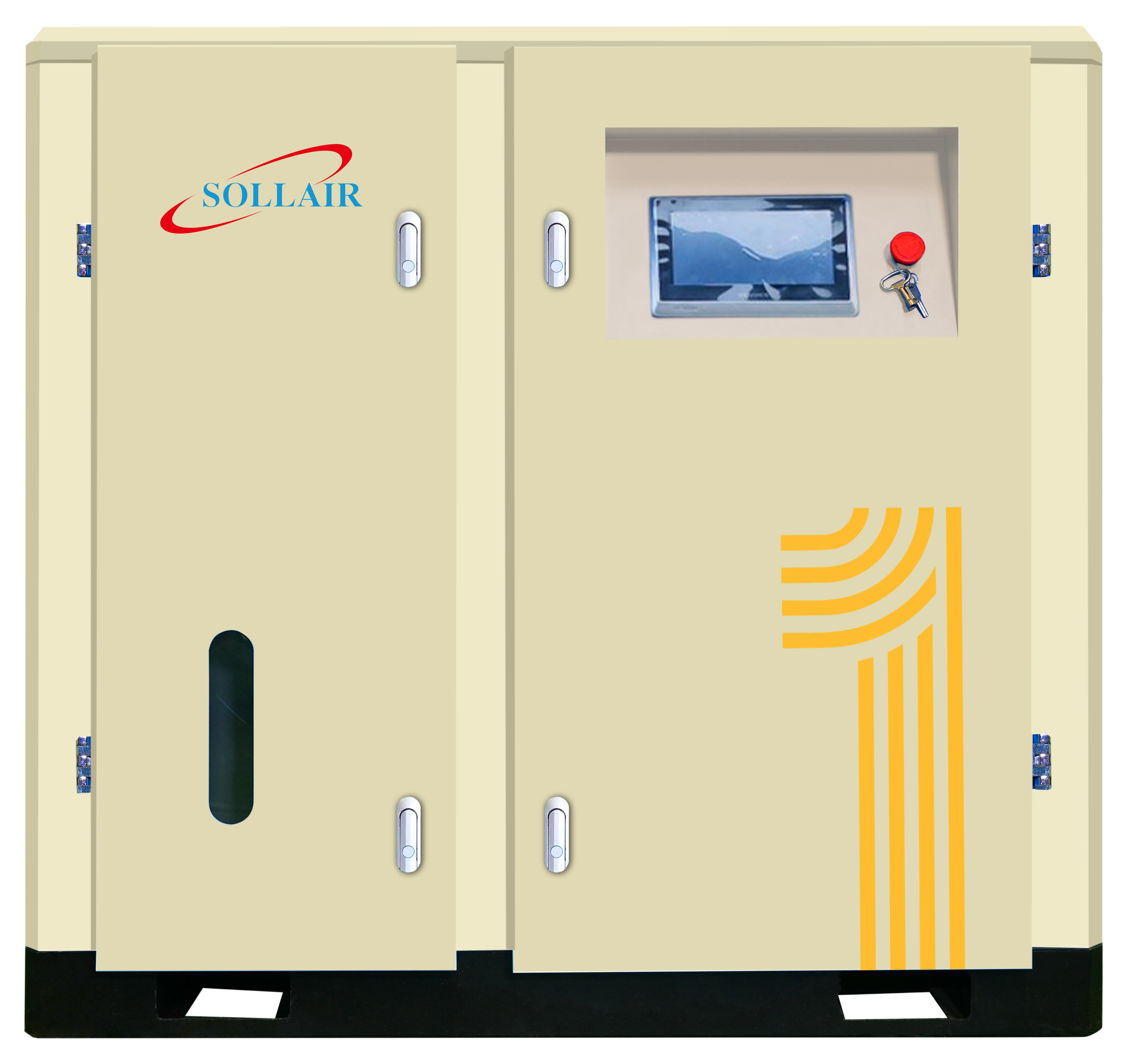

Many industries that require low pressure air still use screw air compressors with a pressure range of 0.7-1.0 MPa, which wastes a significant amount of electricity by using pressure reducing valves to meet the requirements of compressed air usage. In response to the call for energy conservation and emission reduction, Sollair has developed low pressure screw air compressor (One stage VSD screw type) based on market demand.

Features of low pressure screw air compressor :

● High performance is guaranteed by using large rotors and low speeds in the machine.

●The cooling area of the oil cooler has been increased by over 30%, ensuring that it can maintain normal operation without overheating during the summer.

●The internal design of the machine was independently developed, optimizing the input-to-power ratio.